The byford diving accident remains one of the most harrowing incidents in commercial diving history. It occurred on November 5, 1983, at the Byford Dolphin semi-submersible oil rig in the North Sea. Four divers and a dive tender lost their lives due to a catastrophic decompression event. This tragedy shocked the offshore industry and led to sweeping changes in safety protocols.

Moreover, the accident unfolded during a routine saturation dive operation. Divers lived in pressurized chambers between dives. These chambers connected to a diving bell via a transfer trunk. On that day, a critical error caused an explosive decompression.

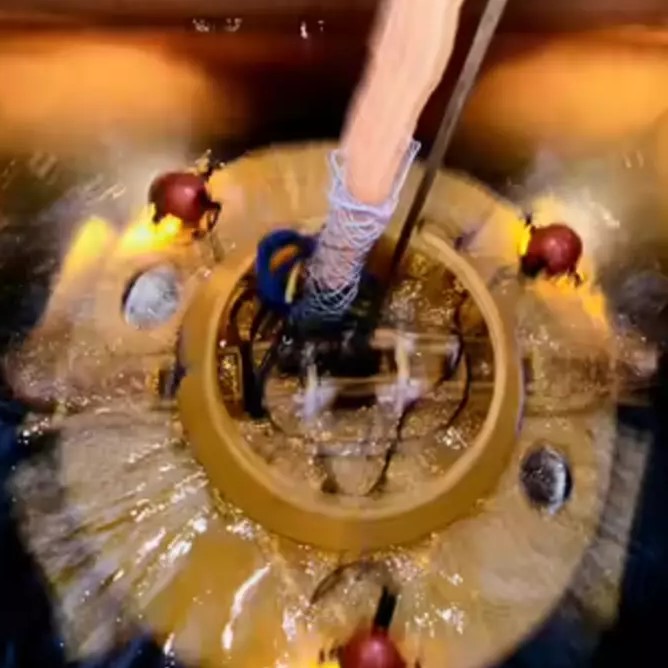

As a result, the pressure inside the trunk dropped from 9 atmospheres to 1 in seconds. This sudden change caused fatal physical trauma. Bodies were torn apart by the force of expanding gases.

Eyewitness accounts described scenes of extreme horror. Blood and debris filled the chamber. Rescue efforts were impossible under such conditions.

Investigations later revealed multiple failures. Equipment design flaws played a role. Human error and lack of standardized procedures worsened the situation.

Despite its age, the byford diving accident still influences modern diving regulations. It serves as a grim reminder of what happens when safety is overlooked.

Therefore, understanding this event helps prevent future disasters. Its legacy lives on in training programs and engineering standards.

What Led to the Byford Diving Accident?

What Led to the Byford Diving Accident?

Several factors contributed to the byford diving accident. First, the diving system used outdated coupling mechanisms. The clamp connecting the diving bell to the trunk could be opened prematurely.

On that morning, the dive supervisor released the clamp before equalizing pressure. This mistake allowed ambient air to rush out violently. The internal pressure dropped almost instantly.

Saturation divers operate under high pressure. Their tissues absorb helium and oxygen. When pressure drops too fast, gas bubbles form in the bloodstream. This condition is known as embolism.

In this case, the decompression was so rapid that it exceeded survivable limits. The human body cannot withstand such forces. Lungs ruptured. Internal organs exploded.

The dive tender inside the trunk died immediately. He had no chance to react. The four divers in the main chamber suffered similar fates.

Communication systems failed to warn the team. No alarms signaled the pressure loss. Operators realized something was wrong only after hearing loud noises.

Procedures at the time lacked redundancy. There were no secondary locks or automatic sensors. One person’s error triggered the entire disaster.

These oversights exposed serious gaps in offshore safety culture.

The Immediate Aftermath and Recovery Efforts

After the explosion, chaos followed. Survivors and crew members faced a gruesome scene. Blood coated walls and equipment. Body parts were scattered across the chamber.

Rescue teams could not enter immediately. The chamber remained unpressurized. Re-pressurizing would have destroyed forensic evidence. It also posed health risks.

Medical personnel arrived quickly. They confirmed all five men were dead. Autopsies later showed massive internal injuries. Gas expansion had literally blown them apart.

Norwegian authorities launched an investigation. They worked with British health and safety agencies. Experts examined the diving system and maintenance logs.

Photos and reports were classified for years. Some details remain restricted. This fueled speculation and conspiracy theories.

Families of the victims demanded answers. They pushed for transparency. Legal actions followed against the operating company.

Memorials were held in Norway and the UK. Divers’ unions honored the fallen. The incident became a case study in risk management courses.

Psychological support was offered to witnesses. Many suffered long-term trauma. Seeing colleagues die so violently left deep scars.

The recovery process highlighted the need for better crisis response plans.

Technical Failures Behind the Disaster

Technical Failures Behind the Disaster

The byford diving accident exposed major technical flaws. The diving bell’s hatch mechanism lacked interlocks. These are safety features that prevent opening under pressure.

Modern systems use mechanical and electronic locks. They ensure the pressure is balanced first. In 1983, such technology was either absent or ignored.

The clamp design was particularly dangerous. It could be removed manually. No warning lights or pressure gauges stopped the operator.

Additionally, the transfer trunk was too small. It provided no room for emergency seals. Once opened, decompression happened too fast to stop.

Materials used in the chamber also came under scrutiny. Seals degraded over time. They were not replaced regularly.

Maintenance records showed missed inspections. Critical checks were skipped due to tight schedules.

Diving supervisors relied on memory, not checklists. This increased the risk of human error.

Equipment from different manufacturers didn’t always fit well. Mismatched parts created weak points.

After the accident, new standards required fail-safe designs. All diving systems now include redundant safety measures.

These changes reduced the chance of repeat events.

Human Error and Procedural Gaps

Human error played a central role in the byford diving accident. The dive supervisor disconnected the clamp without verifying pressure levels.

He assumed the system was safe. This assumption came from routine, not protocol. Over time, shortcuts became normal practice.

Team communication was poor. The diver inside the trunk had no way to signal danger. Intercom systems were unreliable.

Supervisors worked long shifts. Fatigue likely impaired judgment. No rules limited work hours in those days.

Training focused on skills, not safety culture. Workers learned how to dive, not how to avoid disasters.

There was no independent oversight. Company managers prioritized production over caution.

Crew members feared reporting issues. Speaking up might lead to job loss. This silence allowed risks to grow.

After the accident, investigators emphasized procedural reform. Checklists, audits, and supervision improved.

Today, every step in saturation diving follows strict guidelines. One person cannot act alone.

These lessons came at a terrible cost.

How the Byford Diving Accident Changed Industry Standards

How the Byford Diving Accident Changed Industry Standards

The byford diving accident forced major reforms. Regulatory bodies like the HSE (Health and Safety Executive) updated offshore diving rules.

New laws required pressure interlocks. These prevent hatches from opening until pressure equalizes. Sensors now trigger automatic locks.

Checklists became mandatory. Every step must be confirmed by two people. This reduces single-point failures.

Training programs expanded. Divers and supervisors now learn about past accidents. The byford diving accident is a core case study.

Simulations prepare teams for emergencies. They practice rapid decompression drills. Response times have improved significantly.

Medical support is now on standby. Hyperbaric chambers are available nearby. Emergency evacuation plans exist for every rig.

Equipment must meet ISO and NORSOK standards. Regular audits ensure compliance. Non-compliant rigs face shutdowns.

International cooperation increased. Countries share safety data and best practices. The IMCA (International Marine Contractors Association) leads these efforts.

Insurance companies require proof of safety compliance. Premiums depend on audit results.

As a result, fatal diving accidents have declined sharply since 1983.

Psychological and Cultural Impact on Diving Communities

The byford diving accident left deep emotional scars. Survivors and families struggled for years. PTSD affected many involved.

Counseling services were rare at the time. Mental health was not discussed openly. Suffering often went untreated.

Diving communities became more cautious. Trust in equipment and leadership weakened. Workers demanded better protections.

Unions strengthened their advocacy. They pushed for safer working conditions. Collective bargaining included safety clauses.

Stories of the accident spread through word of mouth. Veterans warned new divers. “Never skip the checklist” became a mantra.

Media coverage brought public attention. Documentaries and books kept the memory alive. The human cost became visible.

Artists and writers responded too. Poems, songs, and films honored the victims. Their names are remembered annually.

Today, safety culture includes mental wellness. Crews undergo psychological screening. Support networks are available.

The byford diving accident taught that safety is not just technical. It is cultural and personal.

Frequently Asked Questions

Frequently Asked Questions

What exactly happened in the byford diving accident?

A diving bell was accidentally depressurized. Five men died from explosive decompression.

Could the accident have been prevented?

Yes. With proper interlocks and procedures, it would not have occurred.

Were there any survivors?

No. All five men died instantly.

Is the Byford Dolphin rig still in use?

Yes. It continues operations under strict safety rules.

Why is the accident still studied today?

It changed global diving safety standards. Lessons save lives.

Were charges filed against anyone?

No criminal charges were made. But policies changed drastically.

Can such an accident happen today?

It’s highly unlikely. Modern systems have multiple safeguards.

How fast was the decompression?

Pressure dropped in less than a second. Too fast for survival.

Summary

Summary

The byford diving accident was a turning point in offshore safety history. It revealed deadly flaws in equipment, training, and culture. Five lives were lost in a moment of preventable error.

Yet, their sacrifice led to lasting change. Today’s diving operations are safer because of what was learned. Interlocks, checklists, and training now protect workers worldwide.

Remembering the byford diving accident honors the victims. It reminds us that vigilance saves lives.